SHARPENING SERVICES: Many ………… cost-effective alternative

Southern Carbide Specialists offers carbide slitting saws in a

variety of styles, sizes, and tooth configurations. We also offer

our slitting saws in coarse pitch, fine pitch, or microfine pitch to

accommodate your needs. In order to maintain maximum precision and

symmetry during repetitive machining, blade thickness and axial

radius are kept to strict tolerance figures. Slitting saws can be

used for machining cast iron, steel, and high temp alloys such as

stainless steel and other related steel alloys. Applications include

non-ferrous machining such as aluminum, brass, bronze, magnesium,

zinc, plastics, and non-metals.

If you’re working with non-ferrous metals (metals which don’t

contain iron), Southern Carbide suggests a Coarse Pitch, and we also

offer various levels of finer pitch saws for ferrous metals.

In addition to our various sizes, styles and pitches, Southern

Carbide can also meet your needs for blade thickness. Our slitting

saw thickness tolerance is +.0005 to -.0005”. Saw widths from .005

to .750. We also offer our saws in metric sizes.

Why Carbide?

Carbide metal saw blades provide longer

tool life and decreased cycle times; thus making them highly

effective in long production runs. In addition, carbide is a harder

material than steel and so is also more resistant to wear.

Optimum performance can be achieved by following a rigid set up

with accurate feed and speed, proper tooth geometry, and coolant

use.

Southern Carbide Engineering

At Southern Carbide we

have a solid engineering background and are also able to design saws

based on your job characteristics, tooling sketches, and drawings.

Contact our team of highly qualified engineers to assist you.

JEWELER’S SAWS:

Jeweler’s saws are precision cutting

tools designed for slotting and grooving thin material in which

minimum tooth engagement is desired. Applications include cutting

wire, delicate tubing, sheeting and extrusions. The larger diameter

results in a higher surface cutting speed even at lower revolutions

per minute. Coolant is recommended for the ground teeth. Southern

Carbide offers a range of Jeweler’s slotting saws with OD ranging

from 1 to 4 inches and thickness options between .008-.140. Metric

sizes are also available.

KEYWAY CUTTERS:

Southern Carbide keyway cutters are

made of premium quality sub-micron grain tungsten carbide. This

enables them to make faster, cleaner cuts compared to high-speed

steel. They are super finished to reduce cutter drag. Keyway cutters

are available in straight tooth configurations for working with

harder materials such as high carbon steel. Applications include

machining of keyway grooves including re-cut of worn keyways,

cutting slots, live tooling, and radius work. Finishes are

comparable to a ground surface. Southern Carbide Keyway Cutters are

American Standard with OD ranging from 0.25 to 1.5 inches and a 6 to

16 range of flutes. Metric sizes are also available upon request.

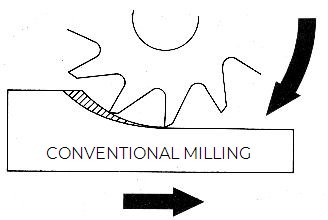

CONVENTIONAL & CLIMB MILLING:

In conventional milling

the cutter rotation is opposite to the direction of the table feed.

In this scenario the width of the chip starts at zero and increases

at the end of the cut. This type of cut requires lower force and is

preferred for roughing cuts. A disadvantage is accelerated tool

wear.

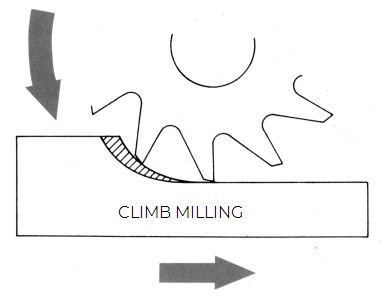

In climb milling, the cutter revolves in the same direction as

the table feed resulting in a better surface finish, longer tool

life, lower power consumption, and ease of fixturing. A disadvantage

is the possibility of backlash depending on the machinery.

|